Pneumatic tools (air power tools) are tools that are powered by compressed gas rather than electricity. While this means that a pneumatic tool will usually need to be attached to a compressor, which are in turn powered by gasoline or electricity - whereas an electric tool just needs an extension cord and a wall plug - they have a number of advantages over their electric brethren.

Pneumatic tools have fewer moving parts and are easier to maintain. They are faster, smaller and, due to the absence of a motor, lighter. There are no concerns over short circuiting or electrocution, making them much more suitable for use in dirty and wet conditions or even under water. They don't burn out if stalled, and deliver more torque. Due to the fact that they don't incorporate a motor, air tools have a vastly higher power density - electric impact tools that deliver the same punch as air tools would be huge, heavy and unwieldy. Some tools just don't come in electric versions - blow guns are an example. Air tools are great for use in industrial facilities, since they usually have air hookups everywhere.

Furthermore, pneumatic tools don't always require compressors. When they need to be used in isolated locations where, for various reasons, a compressor isn't available, they can be powered by attaching them to compressed gas cylinders - carbon dioxide is commonly used for this application.

Due to their strength, power and reliability, air tools are also especially suited to use in remote locations for demanding applications such as oil rig maintenance.

Disadvantages relative to electric tools include the fact that air hoses are bulkier than electric cords, and have less reach. Low-power electric tools are lighter and more portable, and their batteries are very easy to recharge.

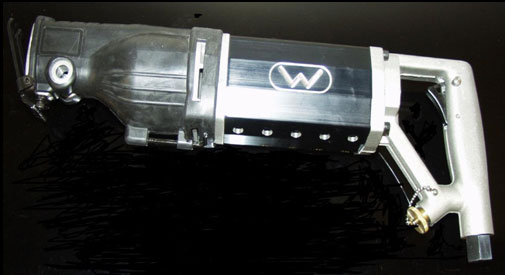

When using an air power tool, make sure that the compressor you attach it to can supply the required air pressure that the tool is rated for. Our powerful Gator reciprocating pneumatic demolition saw requires air pressure of 105-110 PSI. Commercially available user-grade compressors are almost all rated up to 150PSI; however, if you need continuous operation without having to constantly pause and wait for the compressor to refill the tank, you need to look at its air delivery capacity in cubic feet per minute (CFM). For example, our 20-inch pneumatic fan has an air consumption of 60CFM at 90PSI - an ordinary consumer grade compressor from a hardware store is going to rate only a fraction of that. An underpowered compressor means constant interruptions in your work.

Lastly, when using pneumatic tools, it's crucial to make sure the air is lubricated - this will greatly prolong the life of the tool. Air lubrication works by aerosolizing lubricating oil and supplying it with the compressed air to the tool. This oil reduces the friction between moving parts and surfaces, and by so doing, improves efficiency, increases cycling speed and reduces wear and tear on components. Furthermore, lubrication can also help seal the tool more tightly and prevent air leakage around moving parts. HPI Manufacturing, Inc. makes pneumatic air lubricators among other air moving accessories.

Pneumatic tools are your friends when you need fast, powerful, reliable and long-lasting tools to perform demanding tasks in adverse conditions.

|