Assembly & Secondaries

Assembly & Secondary Operations

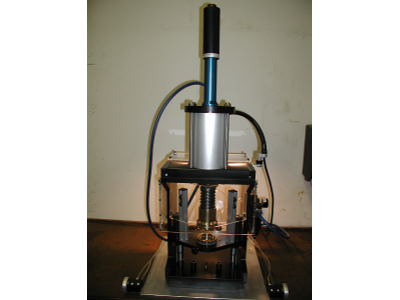

With over sixty years of assembly experience, HPI Manufacturing, Inc offers a wide array of assembly techniques. Our 40,000 square foot facility offers all types of assembly from sonic welding and riveting to complex precision assembly. Our facilities include air presses, drivers, torque controlled screw insertion, and staking. In addition we offer marking, bar code labeling, and packaging.

HPI specializes in outside service management. We have over sixty years of experience in working with cast components of all kinds, as well as, near net shape such as stampings, laser cuts, and spun metal. Our finishing and secondary experience includes heat-treating, plating, powder coating, laser engraving, etc. HPI assists our customers in identifying and qualifying outside service processes that best match their needs.

Turnkey – One-Stop Procurement

HPI Manufacturing, Inc Offers:

- Custom Quality procedures to your specifications

- ITAR registered component management

- DFARS and RHOS compliance

- Certifications to Customer specifications

- Dock to Stock

- Kanban and JIT programs, as well as, Blanket Order Management

- Special Packaging and Bar Coding

- Prototyping and Tooling

- Value Engineered and Economic Design Review