CNC Machining

Flexible, Fast, Economical

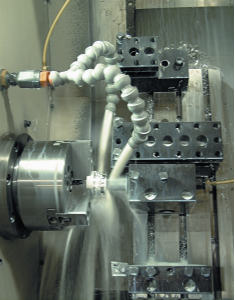

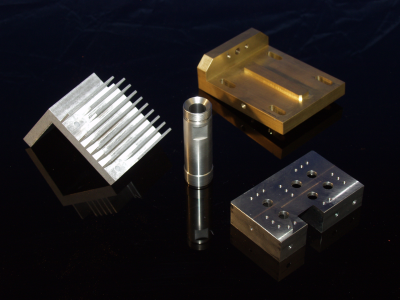

HPI Manufacturing, Inc. offers CNC turning and milling of virtually any material in any size lot. With turning capacities to 15” and a milling envelope up to 30”x 24”x 16”, HPI runs prototype through production lots with quick turn-around and competitive pricing.

Our capabilities include full fourth axis milling, turning centers with live tooling, sub-spindles and bar feed capabilities, as well as a 7 axis Swiss machining center. We also offer full work cell production to offer complete components faster. Our goal is to customize the stream of parts going to our customer to minimize their inventory and eliminate the need for outside secondaries or costly inspection time.

Control is the Key

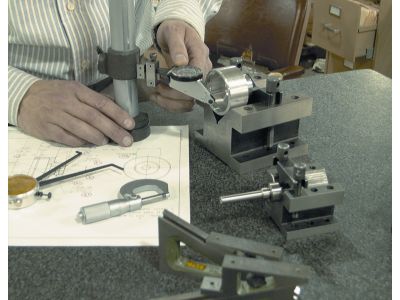

HPI Manufacturing offers customized contract manufacturing. Our approach is to tailor the production process to our customer’s needs. This includes addressing every aspect of an order from customized quality control to lot size and delivery control to customer usage. HPI works with JIT systems, Dock-to-Stock, and KanBan to achieve maximum results in inventory reduction programs.

An ITAR registered company, HPI also offers material certification, DFARS and ROHOS compliant materials at no additional charge.

Complete Secondary and Outside Service

HPI Manufacturing offers complete outside service and secondary processing. We specialize in outside service management with over sixty years of experience with cast components of all kinds and near net shapes such as stampings, laser cuts, and spun metal. Our finishing and secondary experience includes heat-treating, plating, powder coating, laser engraving, etc. HPI assists our customers in identifying and qualifying outside service processes that best match their needs.

Turnkey – One-Stop Procurement

HPI Manufacturing, Inc Offers:

- Custom Quality procedures to your specifications

- ITAR registered component management

- DFARS and RHOS compliance

- Certifications to Customer specifications

- Dock to Stock

- Kanban and JIT programs, as well as, Blanket Order Management

- Special Packaging and Bar Coding

- Prototyping and Tooling

- Value Engineered and Economic Design Review