Engineering & Support

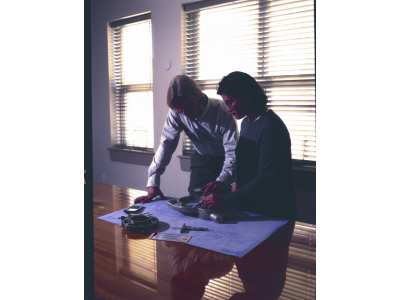

Complete Engineering Solutions

HPI Manufacturing provides engineering support from initial design creation and review to component performance testing and reverse engineering. We offer full 3D CAD services, working with Cad-Key, SolidWorks, and Auto-Cad.

Our value engineering approach addresses component function and value considerations before the design is started. This leads to lower start-up costs, better designs, and shorter lead-times. Our goal is to understand our customers’ requirements and to design our processes around them. Every aspect of manufacturing, from procurement to final testing and delivery is focused on added value to the end user.

Inventory and Cost Control

Our integrated manufacturing system is capable of producing on-hand inventory reports, BOM updates, and complete stock management. HPI can custom tailor lot and shipment size to actual usage. Using tools such as KanBan, JIT, and Dock-to Stock programs, we can radically increase inventory turns. In some cases we have achieved turns of 50 times annually…

Overall product cost can often be lowered through the value engineering process. We specialize in analyzing product cost and the manufacturing process, identifying opportunities to consolidate operations and reduce cost.

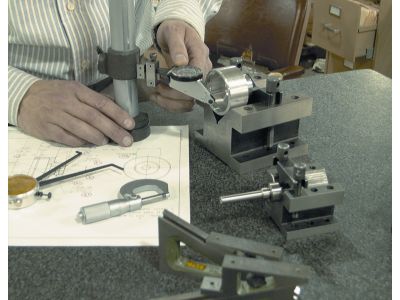

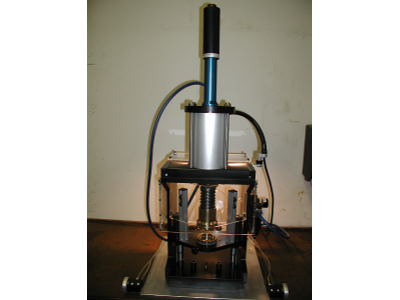

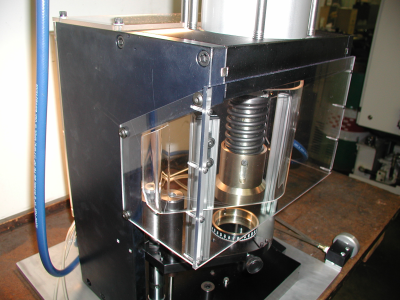

Specialized Tooling and Machinery

HPI Manufacturing, Inc. has been designing and building custom machinery for over 60 years. From in house assembly and testing machinery to custom designed and built machinery for customer use, HPI specializes in precision assembly equipment for unique applications.

Turnkey – One-Stop Procurement

HPI Manufacturing, Inc Offers:

- Custom Quality procedures to your specifications

- ITAR registered component management

- DFARS and RHOS compliance

- Certifications to Customer specifications

- Dock to Stock

- Kanban and JIT programs, as well as, Blanket Order Management

- Special Packaging and Bar Coding

- Prototyping and Tooling

- Value Engineered and Economic Design Review