Injection Molding

Flexible Capacity, Flexible Production

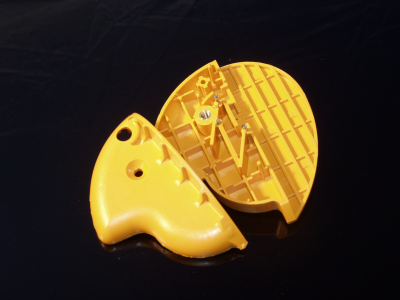

HPI Manufacturing has molding capability from 28 tons to 300 tons of clamping pressure, with shot sizes from fractional grams to 26 ounces. Lot size is completely flexible; HPI will shoot 1 piece to 1 million. HPI uses individual mold frames as well as MUD units. In addition, we work with customers to develop low cost alternatives to complex mold construction such as mold and post machine. We also offer insert molding, secondary operations such as marking, sonic welding, sub-assembly, and packaging.

Wide Range of Material Choices and Color Choices

HPI works with a wide range of engineered and standard plastics including many types of nylon, polyester, polycarbonate, ABS, acetyl, polypropylene, and HDPE. We also handle filled and modified material including glass fill to 40%, UV Stabilization, UL Modified material and high temperature plastics. Al l materials are available with complete material certs and ROHOS compliance.

HPI incorporates powder, concentrate, and compounded color choices. This gives our customers the ability to select virtually and color material at the best price possible. In addition we offer a wide range of secondary operations from marking and packaging to secondary machining operations and assemblies.

Molded Parts to Completed Assemblies

HPI Manufacturing can provide everything from molded components to complex assemblies. Our services include insert molding, over-molding, pad printing, sonic welding, and complete CNC post machining. HPI specializes in finding low volume molding solutions without a complex approach. Our post molding machining capabilities allow us to produced finished components with very difficult to mold features.

Mold Design and Construction

HPI Manufacturing offers complete mold design and building services. Our engineering staff works with most CAD files including CAD-KEY, and Solidworks. We also work with an extensive range of area vendors to assist with services such as stereo lithography, rapid proto-typing, and engraving.

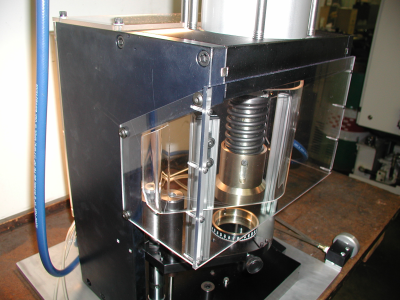

HPI designs and builds stand alone molds and family molds. With forward planning, we can often add shut-offs and interchangeable cavities or cores to accommodate several different parts in one frame. In addition, our extensive CNC machining capability often allows us to offer a simpler mold solution with secondary machining.

Turnkey – One-Stop Procurement

HPI Manufacturing, Inc Offers:

- Custom Quality procedures to your specifications

- ITAR registered component management

- DFARS and RHOS compliance

- Certifications to Customer specifications

- Dock to Stock

- Kanban and JIT programs, as well as, Blanket Order Management

- Special Packaging and Bar Coding

- Prototyping and Tooling

- Value Engineered and Economic Design Review